Blog Details

Polymers for material extrusion additive manufacturing: Part-4

Posted on

#Material Extrusion (FFF,FDM) #All applications #Aerospace #Mechanical #Fashion #Architecture #Health industry #All materials #Polymers

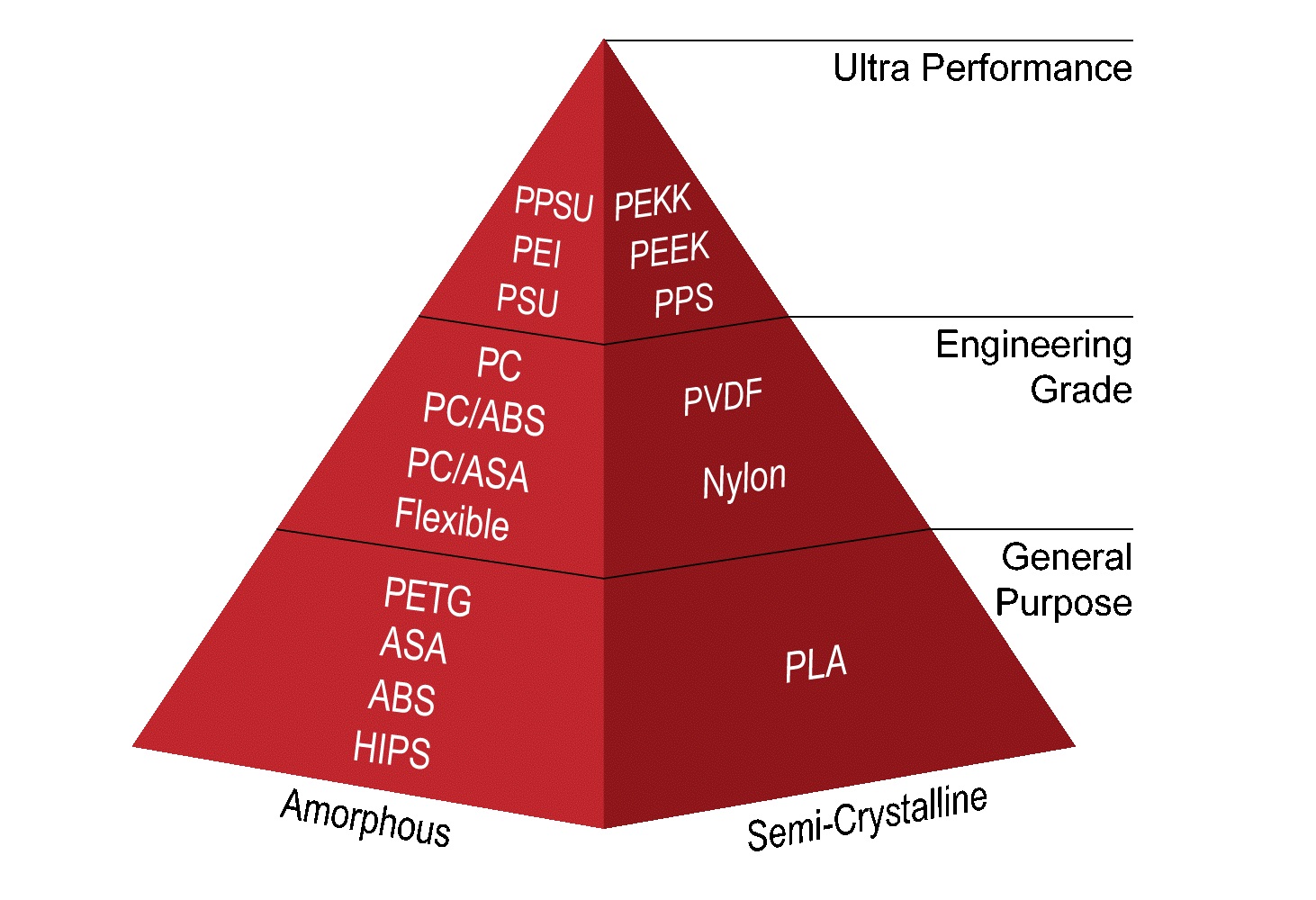

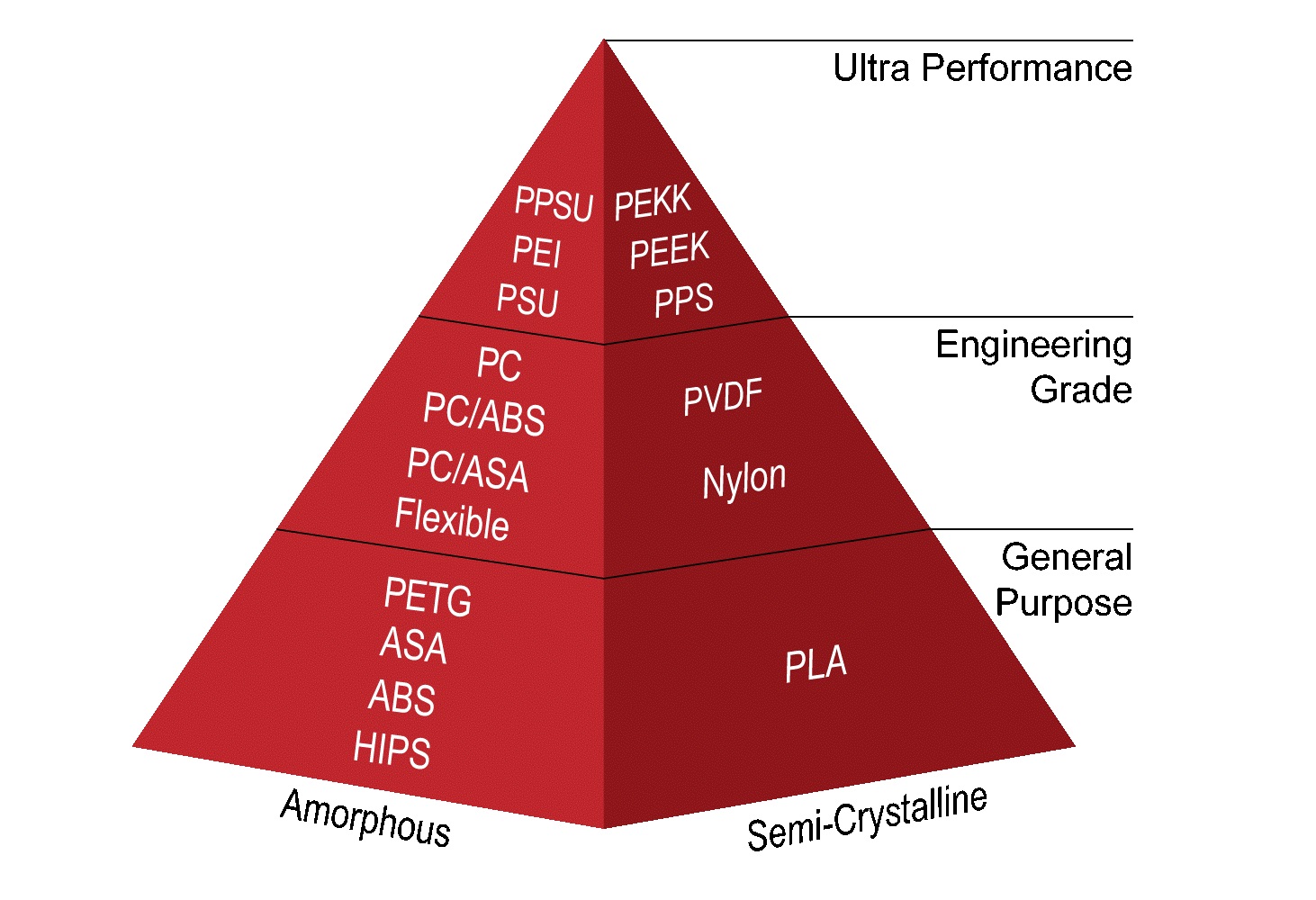

In this blog we will review the ultra-performance grade thermoplastics, which are mainly used for high-end industrial applications. The polymers of this grade placed at top portion in the pyramid of polymers image, seen in the above image. In our previous blogs on polymeric materials, we have covered introduction to polymers, general purpose and engineering grade polymers for FFF 3D printing, and this blog is the final post of that series.

Here, we explore list of commercially available thermoplastic ultra-performance grade polymers, and their applications and advantages. It is to note that the operating temperature of the below polymers is different and some of the materials require high-end FFF printers for processing.

Ultra-performance thermoplastics:

| Materials | Applications | Advantages |

| PSU | automotive,

aerospace, electronics, defense, food service, industrial, plumbing, medical | It

is an amorphous high-temp polymer and has higher thermal properties, it is a

great choice for demanding applications that require excellent thermal,

mechanical, and chemical resistance properties |

| PPS | automotive,

chemical processing, oil and gas, and electronics. making it an ideal material for electrical /

electronics applications, aerospace thermoplastic composites, injection molding

applications | high-performance

polymer that exhibits exceptional chemical resistance along with high thermal

and mechanical properties, inherently flame retardant and self-extinguishing, widely

known as one of the most chemically resistant thermoplastic materials

available, insoluble in any known solvent under 200°C, ability to withstand

hot, humid, and corrosive conditions |

| PPSU | making

it suitable for more demanding applications where higher loads and exposure to

chemicals are prevalent. low-volume injection molds, under-hood automotive

scenarios and heat, chemical, plasma and radiation sterilization | PPSU

is one of the strongest FDM materials outside of our high-performance thermoplastics,

offers strong mechanical properties are complemented by its heat and chemical

resistance, strong, heat-Resistant and sterilizable |

PEI(ULTEM) | can

withstand autoclave operations associated with sterilization and composite

fabrication tooling, aerospace and aircraft applications: Ultem™

resins are used in applications, such as personal service units, oxygen panels

and components, ventilation system components, connectors, cable ducts,

latches, hinges, food tray containers, door handles, and interior cladding

parts, automotive applications like transmission components, throttle bodies,

ignition components, sensors and thermostat housings | offers

superior tensile strength and excellent chemical and thermal resistance, biocompatible,

possessing high heat resistance and thermal stability, exceptional tensile and

flexural strength, making it an excellent electrical insulator, it is a high-performance

polymer that combines excellent thermal properties, exceptional dimensional

stability, inherent flame retardancy, and good chemical resistance |

| PEEK | used

in the oil/gas, automotive, aerospace, industrial, and chemical processing

industries, ideal for aerospace applications, exterior parts of aircrafts, medical

and healthcare: biocompatible material, Handles of dental syringes, sterile

boxes, load bearing implants | inherent

flame resistance, outstanding mechanical, thermal,

and chemical resistance, low smoke generation, excellent resistance to a broad

range of chemicals |

| PEKK | suitable

for aerospace applications, automotive, industrial and chemical industries for

structural components including gears, bushes, friction bearings, shafts, ball

valve seals, wear plates, yarn & thread guides, and small precision

(rotational) parts. Because of its inertness and outstanding chemical

resistance, PEKK is suitable for sterilization and therefore can be used for

medical and food contact applications such as dental tools, medical body

implants, and cookware | excellent

mechanical properties that include high strength, high heat resistance,

toughness and wear-resistance, chemical resistance and minimal outgassing, these

superior qualities make it a lighter alternative to aluminum and steel, because

of PEKK’s excellent mechanical properties, including high stiffness, high

toughness and long-term creep, fatigue and wear resistance, mechanical parts

made of (fiber reinforced) PEKK can replace steel in many applications |