Blog Details

Polymers for material extrusion additive manufacturing: Part-3

Posted on

#Material Extrusion (FFF,FDM) #All applications #Aerospace #Mechanical #Fashion #Architecture #Health industry #All materials #Polymers

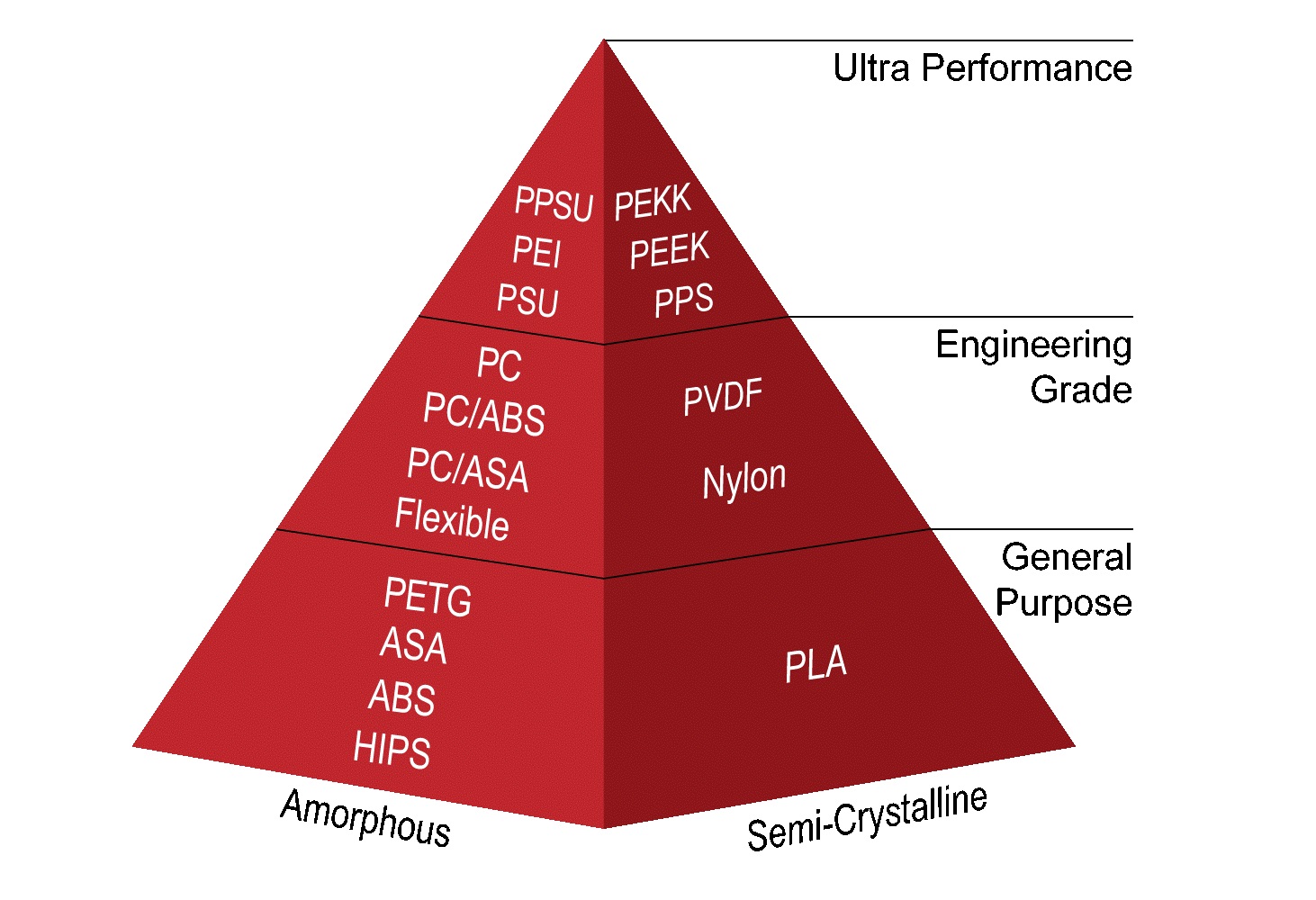

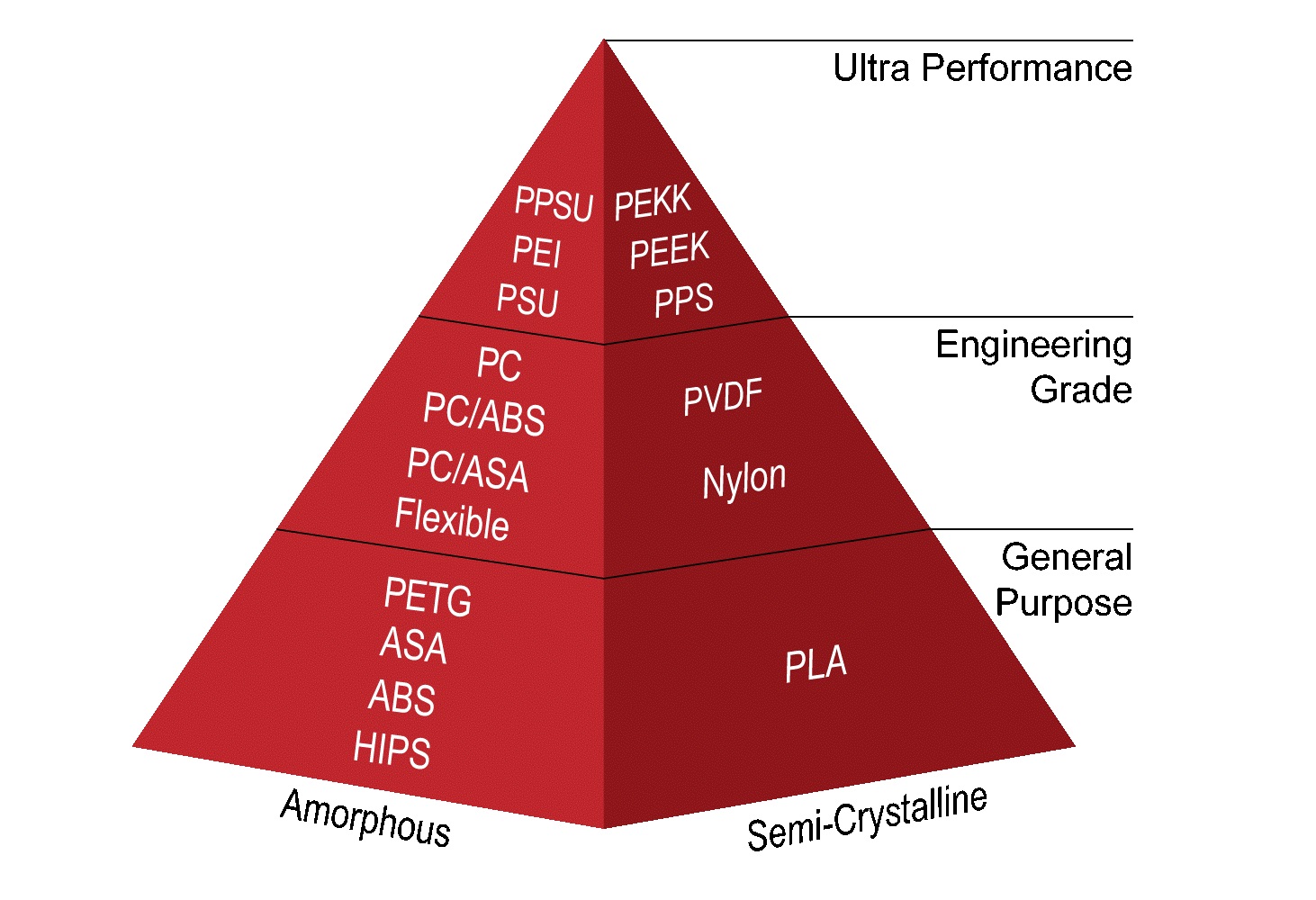

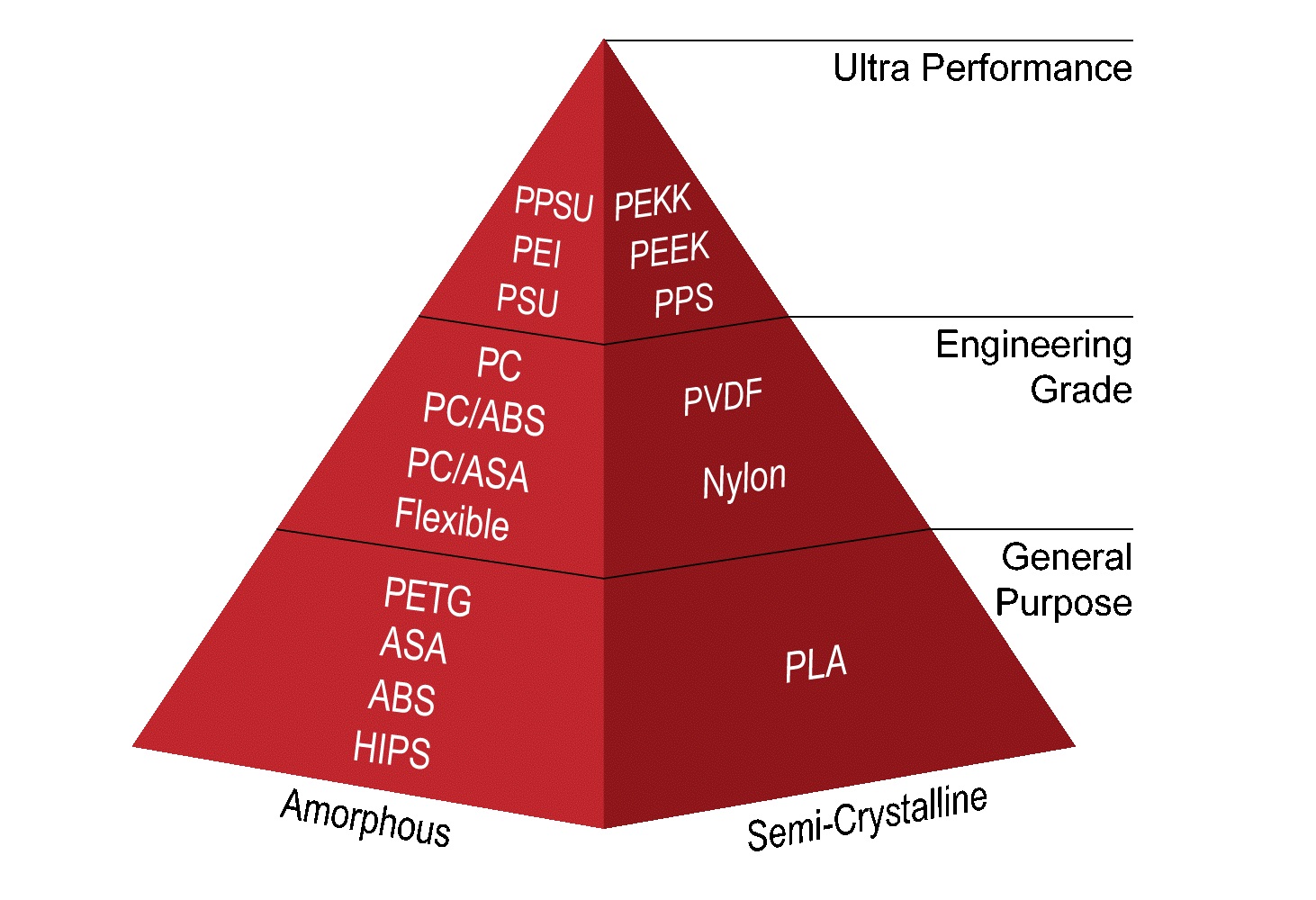

Engineering grade thermoplastics are another class of thermoplastics, which are mainly used for engineering applications. This blog is following our previous blogs on introduction of polymeric materials and general purpose thermoplastics for FFF 3D printing.

Here, we explore list of commercially available thermoplastic polymers of this grade, and their applications and advantages. It is to note that the operating temperature of the below polymers is different and some of the materials require high-end FFF printers for processing.

Engineering grade thermoplastics:

| Materials | Applications | Advantages |

| Nylon | jigs, fixtures tools, low-volume production and highly customized parts, applications involving snap-fit closures, tools with press-fit inserts, components subject to high vibration and parts requiring threaded inserts | exceptional toughness and resistance to hydrocarbon-based chemicals, while maintaining a smooth, lubricious surface quality, smooth surface finishing for prototypes, combined strength with excellent fatigue properties suitable for repetitive closures, snap fits and vibration-resistant parts |

| PVDF | great fit for applications that will be exposed to harsh environments | exceptional thermal and chemical resistance |

| PC | automotive, aerospace and medical, ideal for demanding prototyping needs, tooling and fixtures, and patterns for metal bending and composite work, conceptual modeling, functional prototyping, manufacturing tools and production parts | high tensile and flexural strength, tough and heat resistant, superior durability and strength, offers accuracy, durability and stability, producing strong parts that can withstand functional testing |

| PC-ABS | power-tool prototyping and industrial equipment manufacturing, functional prototyping, tooling and low-volume manufacturing | tough, durable and heat-resistant, works with soluble support, so complex parts with deep internal cavities take no extra effort, delivers excellent feature definition and surface finish |

| PC-ASA | UV-stability makes it an ideal material for outdoor applications, tooling, automotive, marine, and automotive exterior applications such as mirror housings, cowl covers, radiator grills, and sensor housings | highly UV-resistant, exceptional mechanical and thermal properties - coupled with excellent UV-stability |

| TPU | TPU is a elastomer (flexible) material and its applications includi flexible hoses, tubes, air ducts and vibration dampeners | resilient, flexible thermoplastic, combining flexibility and stretch with abrasion and tear resistance |