Blog Details

Polymers for material extrusion additive manufacturing: Part-2

Posted on

#Material Extrusion (FFF,FDM) #All applications #Aerospace #Mechanical #Fashion #Architecture #Health industry #All materials #Polymers

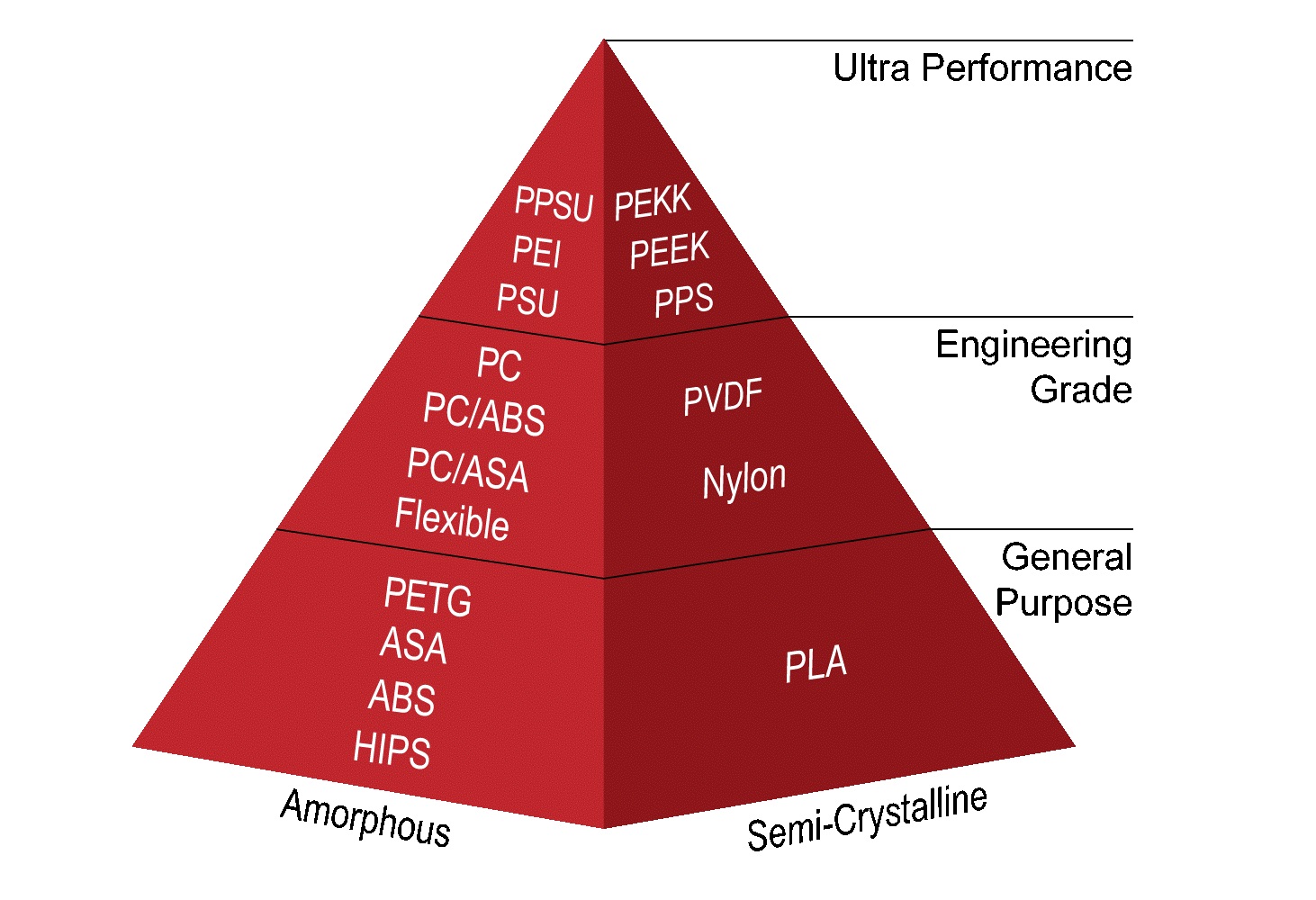

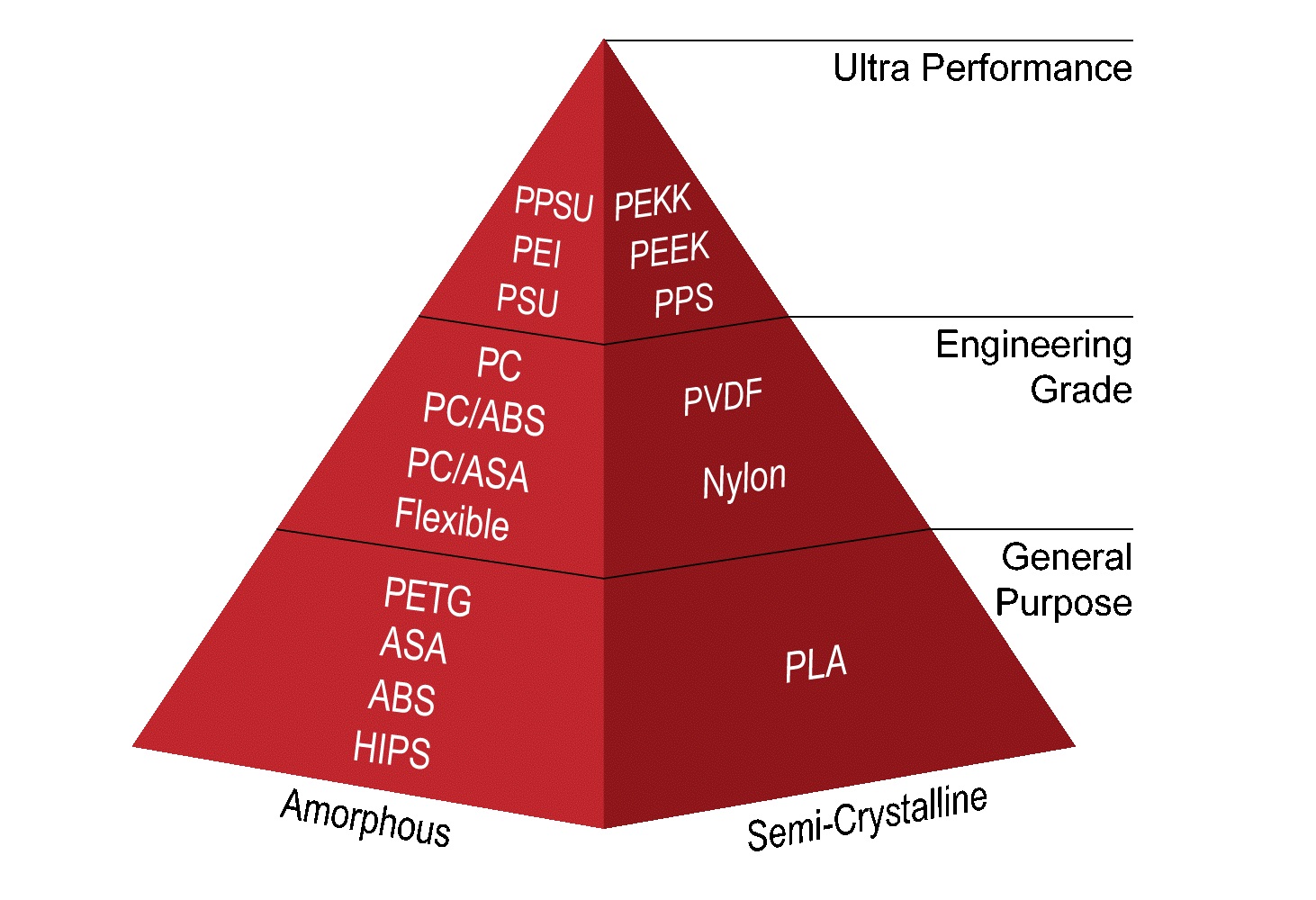

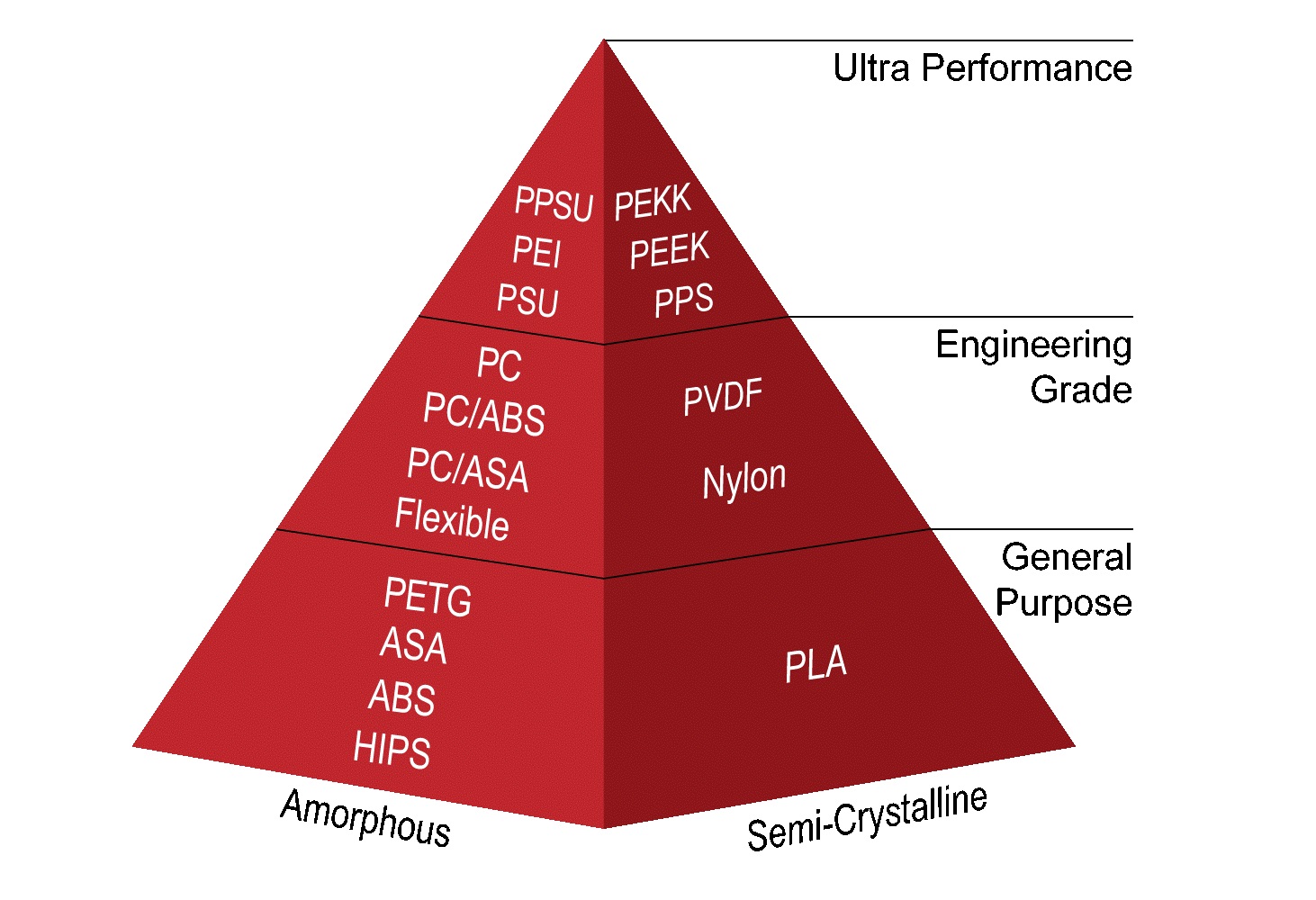

Following our previous blog on introduction of polymeric materials

for FFF 3D printing, which describes about three different groups of

thermoplastic materials: General purpose, Engineering grade and

ultra-performance thermoplastic materials.

Now, let us dig little deeper into the thermoplastic polymeric materials and their advantages and specific applications. List of commercially available polymers provided below. It is to note that the operating temperature of the below polymers is different and some of the materials require high-end FFF printers for processing.

General purpose thermoplastics:

| Materials | Applications | Advantages |

| ABS | concept

models, functional prototypes, tools, end use parts | stronger

layer bonding, better mechanical properties |

| PLA | concept

models, medical applications, functional parts | available

in transparent colors, fast printing, better mechanical properties, requires less heat and power to print parts, bio-compatible |

| PETG | concept

models, fashion industries, medical applications | stronger,

temperature resistant and durable, stronger layer bonding, lower shrinkage,

chemical resistance, odorless during printing, lustrous surface |

| HIPS | support

structures for overhangs while 3d printing | dis-solvable

filament, easy removal |

| ASA | end-use

parts for outdoor commercial and infrastructure use | UV

stability |